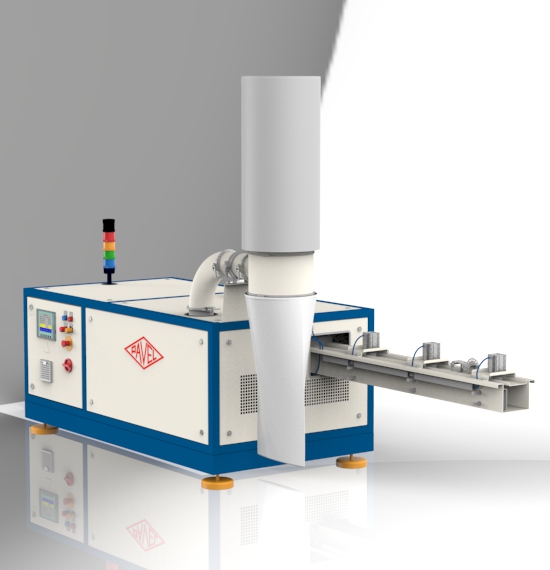

Film Compactor KP 101

The smallest in the product family. The KP 101 overcomes effortless your stamp wastes or your package wastes.

→ read more

Whether during the extrusion of flat or deepdrawing films or the packing production, whether during printing or carrier-bag production punch wastage and edge trimmings are generated at all places where films are produced and processed.

The produced waste - whether crude material or composite material - doesn't usually contribute to the profit and causes instead just more costs.

What usually happens is that valuable materials are filtered out of the operational process in a cost intensive way. Foil winders, shredder troughs or presses are putting a strain on the performance of your company.

We have tackled this "never-ending story" problem and developed a type of machine which is capable of taking up edge trimmings and punch wastage directly on-site and process them into highly compacted bars without any further devices.

And that's how it works! The pavel-compactors are directly connected to the waste producing machines tube system. A connection to the already an existing suction solution is of course possible.

The base material is pulled in automatically into the suction and compression cylinder. With a piston the highly compacted foil is transported into the heat channel. The piston compresses the foil under heat into a solid block. The endless stand this process generates is cut into individual pieces of preselected length.

A peripheral 1-on-1-binding of our compactors on your cutting and extrusion lines minimises the failure risk of several facilities at once and therefore contributes to the safe performance of your production process.

The compact and modular setup of our machines allows for standalone use of the compactors or as an addition to existing systems. Your individual customer requirements will be considered at every step. The peripheral separation of cutting and extrusion lines allows for a varietal separation of the material. As a result you can add the material to the recycling system and earn money with that.

Next to reliability the safety of our compactors is an important issue. Our machines are equipped with a widely visible tower light and an automatic fire incident device. The cases of the machines can only be opened with a special key to ensure that only qualified personal can access the machinery. All dangerous machine parts are inside the case, your employees are never exposed to any risk of injury.

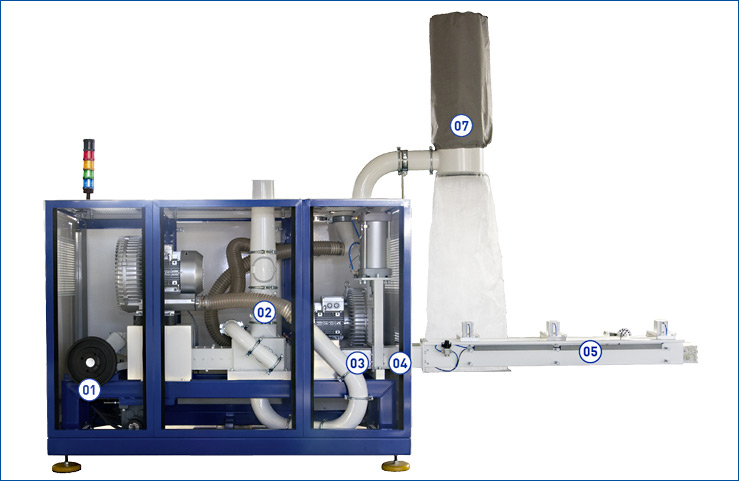

01 crankshaft drive with compressor piston

02 suction and compression cylinder

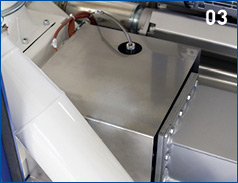

03 temperature controlled heating channel

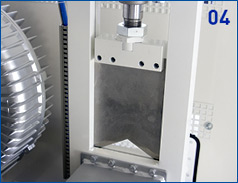

04 cooling channel with length-cutting

05 outlet channel with pneumatic compression regulation

06 touch-based electronic control

07 user-friendly exhaust filter

The smallest in the product family. The KP 101 overcomes effortless your stamp wastes or your package wastes.

→ read more

The big brother with distinctly more suction performance. Optically very similar to the KP 101, this compactor can ...

→ read more

The big compactor KP 2000 is the first choice for the active "edge trim extraction". Whether directly next to producing machine or on the other side ...

→ read more